Carbon-Negative Technology

Vermiculite is Produced From the Ore that is Mined using Open-Pit Methods

The crude ore is crushed and the raw Vermiculite is separated and sorted into size fractions, then sent to a natural gas dryer. The concentrate is transported by truck or train to the nearest ports and shipped to its destination. Upon arrival the material is transported to the expansion plant fed through a natural gas furnace fired by natural gas to exfoliate the material into its final form. The material is then packaged and shipped to its final destination. The production of vermiculute utilizes large quantities of natural gas and diesel fuel generating significant carbon positive emissions. Open pit mining incurs changes in land use.

Bio-Vermiculite is Produced from Pine Forest Logging Residues Harvested According to the Sustainable Forestry Initiative Standards

The pine residue feedstock is collected and brought the the manufacturing facility where it is sized and sorted. This feedstock is heated to over 900 °C in an oxygen-free environment where the hemicellulose and cellulose vaporizes leaving the underlying pine pore structure. This process also transforms the pine pores into a graphitic form that resists degradation in the soil. Otherwise the residuals would convert to CO2 in a controled burn or through soil microbiological respiration. The production of Bio-Vermiculute is "carbon negative" locking down the carbon sequestred by the pine forest for centuries. Bio-Vermiculite does not contain Vermiculite.

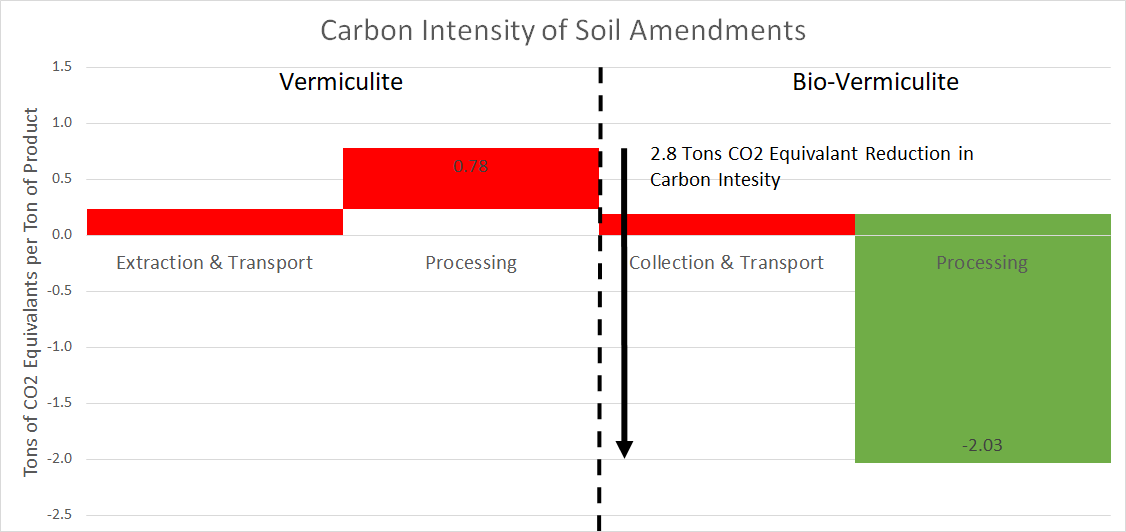

Bio-Vermiculte Sequesters 2.8 Tons of CO2 Equivalent per Ton of Displaced Vermiculite

Download the Product Sheet

Learn more about why biovermiculite is the best choice for you.